Unsere Webseite und das Besuchen der Webseite ist CO2-neutral.

Die erzeugten CO2-Emissionen werden neutralisiert.

Aucun produit

Les prix sont TTC

Product successfully added to your shopping cart

There are 0 items in your cart. There is 1 item in your cart.

En savoir plus

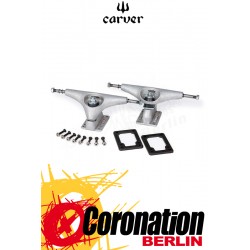

Carver C7 Truck Set - Surfskate Achsen

Carver Truck Set 6.5" C7 Front C2 Rear, 2 Sets Risers raw

Carver C7 Truck Info

The Carver C7 is our Patented front truck designed to create the same fluid dynamic for a skateboard that a surfboard has in the water. What gives it this ability is the extra axis of movement provided by the trucks rotating arm, giving the nose of the board lateral thrust, in addition to the usual rail-to rail turn. With this extra turning capacity, the back truck becomes a pivot from which to snap turns, the way fins hold in the water while the surfboards rocker slides on the surface of a wave.

This dynamic also creates the much sought after ability to pump the board for speed, and is the feature unique to Carver that finally delivers on the long-promised feel of surfing a skateboard. Riding fakie is also like riding a surfboard, but backwards, where the nose feels squirrelly, and for this reason the C7 is a front truck only. The arm rotates smoothly on precision industrial thrust bearings, and is dampened by a fully adjustable, heavy-duty internal die spring that allows each rider to customize the feel of their board. But at its core, the C7 is still a skateboard truck, with a traditional hanger and standard new-school mounting hole pattern ( 2.1?, or 2 3/32? long) that will fit any new-school skateboard deck, while preserving the original wheelbase.

Mounting Instructions

When mounting your new Carver trucks, bolt the standard truck at the tail of the board as you would any typical truck, with the kingpin and bushings facing towards the center of the board, and bolt the C7 on the nose.

Bolt the front truck to the nose of the deck with the kingpin and bushings facing inwards towards the center of the board. The rounded end of the truck with the arm bearings faces towards the front. People often ask about mounting a C7 to the back as well, but this is not very practical. The stable pivot of the back truck is an important component of the system, and without it you compromise control, like riding a surfboard without fins.

RISERS

Riser pad thickness to control wheelbite is roughly a factor of wheel diameter, so the larger the wheel, the taller the risers. There is no set formula, as everyone rides differently, so find out what works best for you.

BOARD LENGTH

Board length and shape plays an important part of the overall performance of the completed skateboard. Shorter boards are more maneuverable and pump easier, while longer boards are more stable and handle speed better. Wider boards generally provide better turn leverage than narrow boards. Trying out a few different lengths will give you a real sense of the feel between wheelbases. You can also refer to the SKATEBOARDS section of the website for descriptions of the various board lengths and their handling characteristics..

BREAK-IN

Break-in time for the bushings is usually about an hour of riding, where the slippery new bushings have a chance to wear a little and stick to the metal surfaces, reducing the range of turning travel at the extremities, controlling wheelbite and increasing spring-back and rebound. Pumping the board on the flats is a good way to break in the bushings and get a feel for the boards handling.

ADJUSTMENTS

Adjusting the trucks can vary the overall feel dramatically. For the C7, the bolt located at the front tip that holds the arm bearings together should be tight but not binding, so it can rotate freely without play. IT DOES NOT ADJUST TENSION! Over-tightening the Pivot Bolt will prevent proper rotation of the arm, and will likely crack one or more of the Thrust Washers, requiring replacement. The Spring Bolt, located on the baseplate facing the inside of the board, adjusts the inner spring that controls tension on the arm. Using the Carver PIPEWRENCH, or any standard skate tool, play with the relationship of this tension and the tightness of the bushings for a feel that suits your style of riding. The adjustment of the back truck also plays an important part in the overall feel, so when tuning up your board, remember that its the other half of the whole system.

The Carver C7 was designed to be very low maintenance, but it does have a few mechanical parts, like bearings and a spring, so a little care will give you maximum performance and extend the life of your truck. A light machine oil in the thrust bearings will prevent them from rusting and keep them rotating freely, just like your wheel bearings. The spring parts are protected inside the baseplate and need little maintenance, but if they get squeaky, an application of grease on the spring parts will keep everything moving smoothly and quietly. First remove the truck from the board, then unscrew the spring bolt and slide it out and the spring parts can be easily removed. Grease all the moving parts and reassemble: place the spring nut against the inner cavity wall, drop the spring into the housing and snug it up against the nut, hook the link onto the link pin and snap it over the spring. Finally, re-insert and tighten the spring bolt, starting the threading first by hand to avoid cross threading. All maintenance can be performed using a standard skate wrench, like the Carver PIPEWRENCH. While at first glance the C7 may look complicated, its actually very simple to take apart and reassemble. The exploded-view drawing shows you at a glance the order and names of all the parts for quick reference.

Mounting Instructions DISASSEMBLY

1. First, remove the TRUCK from the BOARD.

2. Next, disassemble the SPRING SYSTEM by unscrewing the SPRING BOLT, located on the SPRING HOUSING of the BASEPLATE, and pull it out.

3. Unhook the LINK from the LINK PIN by lifting it off the SPRING.

4. Remove the SPRING and the SPRING NUT from the housing.

5. Remove the ARM by unscrewing the PIVOT BOLT, located in the center of the stack of THRUST BEARINGS connecting the ARM to the BASEPLATE, while pressing on the LOCKNUT underneath to keep it nested in the BASEPLATE and prevent it from rotating.

6. With the truck upside down, lift the BASEPLATE off the arm, while the THRUST BEARINGS are held stacked on the ARM.

7. Remove the HANGER just like on any standard skate truck; simply unscrew the LOCKNUT and slip the HANGER and BUSHINGS off the KINGPIN.

ASSEMBLY

Assembly is essentially the reverse; put the HANGER on, attach the ARM and then install the SPRING SYSTEM.

1. Assemble the HANGER as you would on a standard truck.

2. To attach the ARM, first stack the smaller THRUST BEARING and WASHERS onto the PIVOT BOLT. The bearing should be sandwiched between the three washers, with the pair of hardened THRUST BEARING WASHERS on either side of the THRUST BEARING and the plain TOP WASHER directly in contact with the PIVOT BOLT head.

3. Slide the PIVOT BOLT into the ARM through the BRONZE SLEEVE. Turn the ARM over, holding the PIVOT BOLT in place with your finger, and stack the bottom THRUST BEARING ASSEMBLY onto the BEARING CORE on the ARM.

4. Slide the BASEPLATE on and finger-start the LOCKNUT. Press the LOCKNUT into the casting so it locks in place and then tighten the PIVOT BOLT all the way down. The BEARINGS should be as tight as possible but still rotate freely. If its too tight the ARM will bind, if its too loose it will rattle when you ride. You may find that you need to snug it up once after riding it a bit, as the bearings seat. This bolt DOES NOT adjust tension, and should not be over tightened.

5. To assemble the SPRING SYSTEM, first pace the SPRING NUT in the SPRING CAVITY against the inner casting wall.

6. Drop the SPRING into the housing and push it up against the SPRING NUT.

7. Hook the LINK onto the LINK PIN and press it down over the SPRING.

8. Slide the SPRING BOLT into the base and screw it into the SPRING NUT, starting it by hand first to avoid cross-threading.

9. Adjust to your desired tension.

Info

Trucks: C7.4 Front Truck, C2.4 Rear Truck

C7.4 Bushings: Top - 0.375" 95A Conical= Bottom - 0.55" 95A Barrel

C2.4 Bushings: Top - 0.58" 89A Conical= Bottom - 0.65" 89A Barrel

Risers: 2 Risers

Hardware: 1 1/4" Stainless Steel

Lifetime Guaranteed Components: Hanger, Arm, Base

Axle Width: 9"

Truck Height: 2 7/8"

Material: Aircraft Grade, Industrial Recycled A356 Aluminum, heat treated to Rockwell T6

Weve been busy making improvements to all our trucks, and this staple of the line The Carver C2.4 is no exception. This SKP (Standard King Pin) style of truck is the rear truck to both our CX and C7 front trucks. We focused on its performance as a smooth-turning rear pivot that coordinates with the more radical turning of the front by matching rail range but reducing turn rate. This makes it an ideal stable pivot to rely on under your back foot while you pump the board. We tested many geometries and found that most trucks designed to function well as pairs need to have some pumping properties to feel good when ridden together, but since our front trucks are already the dynamic engine of the pair it was actually necessary to moderate the performance of the rear truck. When you push into the tail you dont want to feel too much turn, as that results in tail drift. You also dont want it to dig into a turn, as you are relying on that rear pivot for stability. During our testing we also learned that besides the wheel formula, truck geometry is an important part of grip and traction. So we designed the performance of the new C2 to allow you to push hard into the tail and have the wheels bite into the pavement without any of the subtle chatter that results in traction break. These were not properties we theorized, but were purely the result of extensive experimentation and prototyping. We got what we wanted by skating hard and taking notes. And what we got is a back truck that holds the ground in the deepest turns, feels solid underfoot and snaps back to center with exceptional rebound.